Combines the Robustness of Centrifugal pumps, Efficiency of VT, Reliability of Induction Motors in a Submergible enclosure

Low Energy Cost

Low Energy Cost Based on VT Bowl hydraulics, the Bowl Efficiency is nearly the same as that of VT pumps. However the Elimination of Line Shaft, Coupling, Thrust Bearing, Spider, Shaft Enclosing Tube, Forced Water Lubrication system, etc causes a reduction in Mechanical power consumption (kW) as well as Hydraulic (m) losses resulting in Wire to Water (Overall) pump efficiency being slightly better than VT pumps (especially in cases of deeper setting lengths).

Low Life Cycle Costs (LCC)

Minimal maintenance & Low power Consumption

Robust & Reliable

No breakdown even in high silt levels & for deeper column Lengths. Over-safe Design & Smart Protection Systems result in high Reliability.

User Friendly

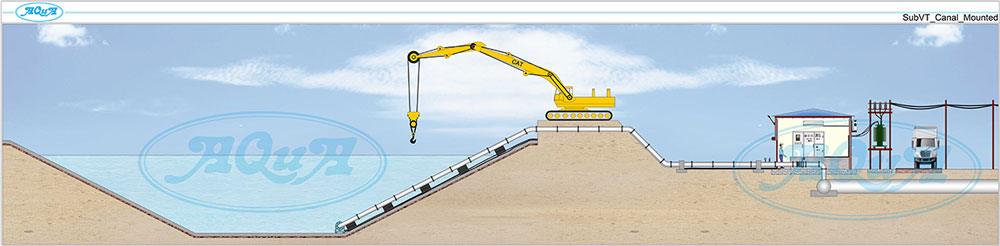

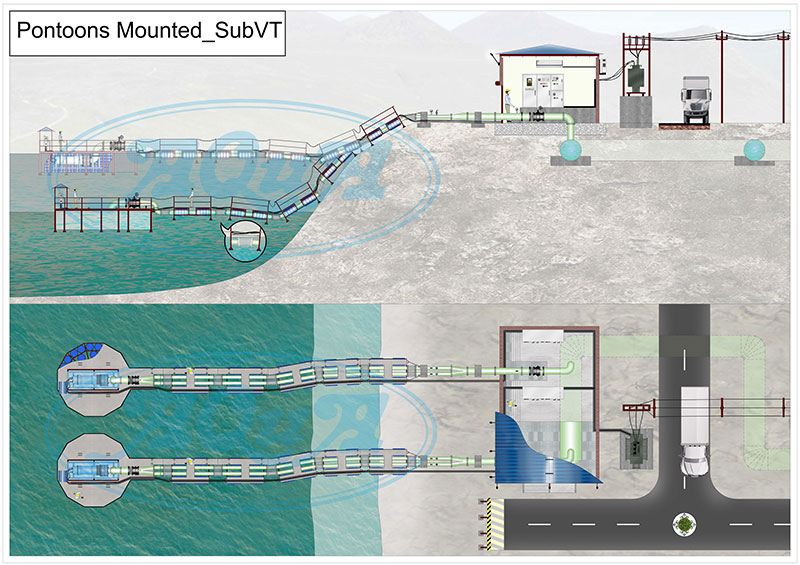

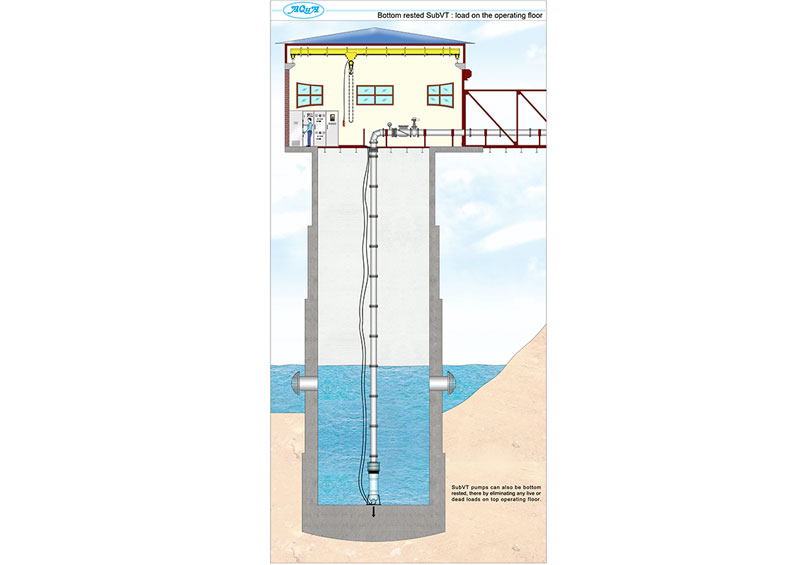

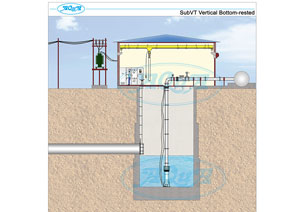

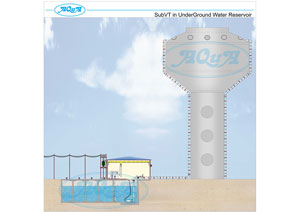

Compact, Fully Portable & Flexible - can be installed either in Sump or directly in Water Body Vertically (& most models can be installed Horizontally also)

Simple & Quick to Commission

Due to mono block design; no need to align shaft, coupling, thrust bearing, spider etc.

Maintenance Free

Requires No Consumables or Routine maintenance (like Priming, Oiling, Greasing, Gland Tightening, Shaft Alignment, Dry Run prevention etc.)

Minimal Noise, Vibration & Heat Emission

No Auxiliary & Ancillary systems required like Forced Water Lubrication, Thrust Bearing, cooling system, Motor Heat Exchanger.

-

Installations

-

Technical Specifications

Pump Size DN 40 to 800 mm Capacity Q Up to 8100 m3/hr Head H Up to 280 m Motor Rating P Up to 1600 kW Temperature t Standard up to 50˚C Supply Options 3 Phase, 415 V, 690 V, 3.3 kV, 6.6 kV Speed n 3000, 1500, 1000, 750, 600, 500 rpm (Synchronous) -

Typical Performance Range

-

Application