Combines the Robustness of Centrifugal pumps, Efficiency of VT, Reliability of Induction Motors in a Submergible enclosure

Substantial Savings

Reduction in Pump House Space, Construction cost & Suction piping Manifold complexity.

Low Energy Cost

Wire to Water efficiency is at par with Centrifugal / VT pumps & substantially higher than Water filled Submersible, Polder pumps.

Low Life Cycle Costs (LCC)

Minimal maintenance & good efficiency

Robust & Reliable

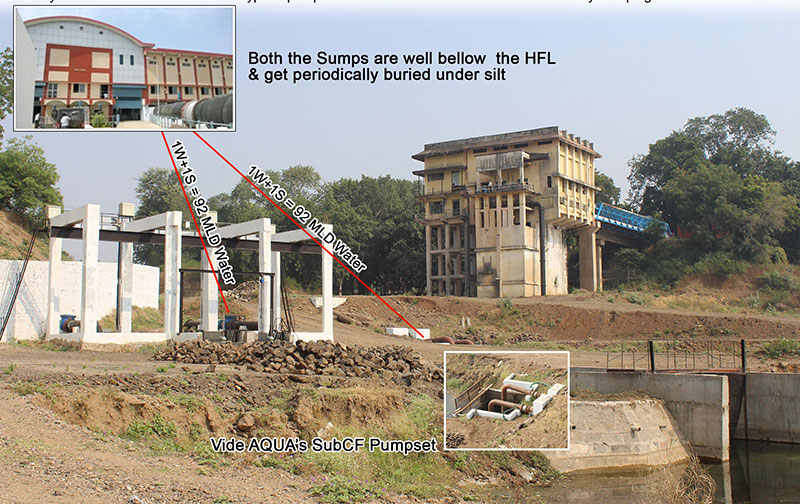

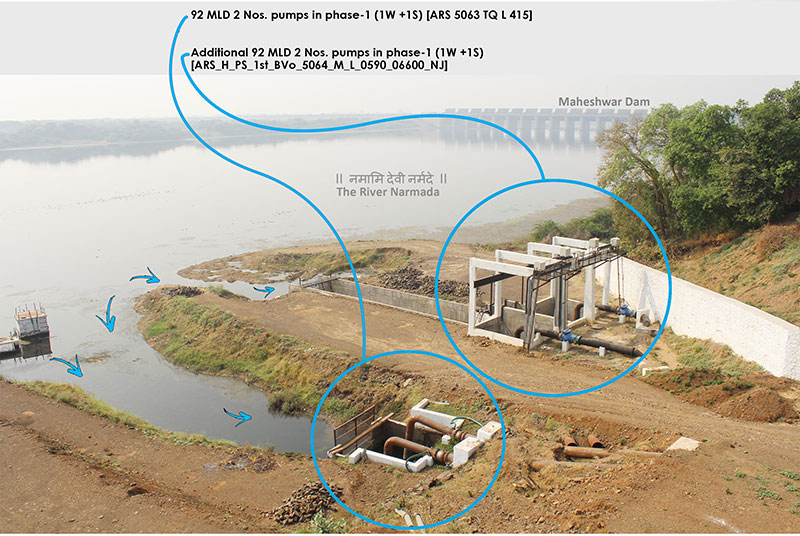

No breakdown even in high silt levels. Over-safe Design & Smart Protection Systems result in high Reliability.

Weather Proof

No pump room requirement -No risk of cavitations. No damage due to Flood or Rains

User Friendly

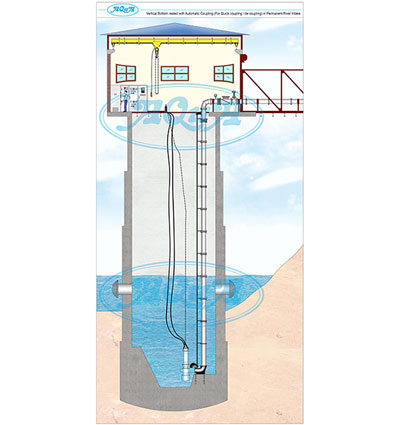

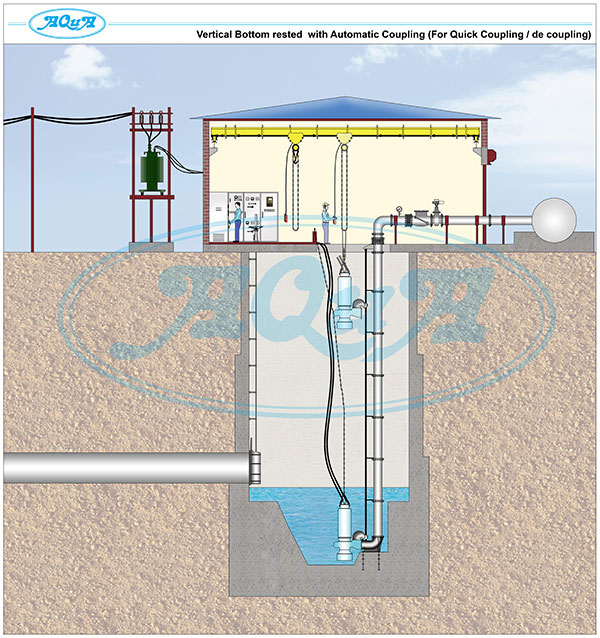

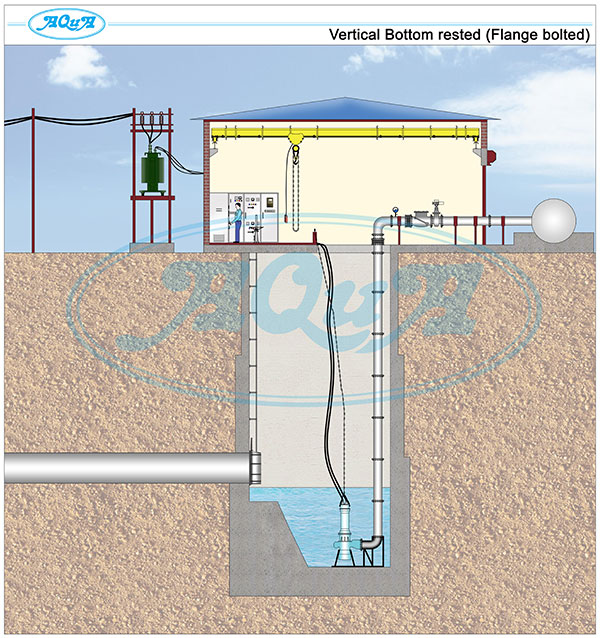

Compact, Fully Portable & Flexible - can be installed either in Sump or directly in Water Body, Vertically or Horizontally; Permanent or Portable.

Simple & Quick to Commission

Due to minimal civil structure requirement, projects can be commissioned much faster.

Maintenance Free

Requires No Consumables or Routine maintenance (like Priming, Oiling, Greasing, Gland Tightening, Shaft Alignment, Dewatering of Gland/ Leakage or Seepage into the Dry Pump room etc.)

Minimal Noise, Vibration & Heat Emission.

-

Installations

-

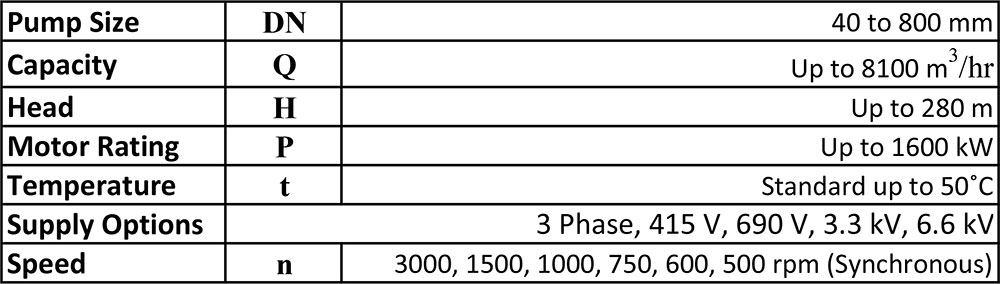

Technical Specifications

-

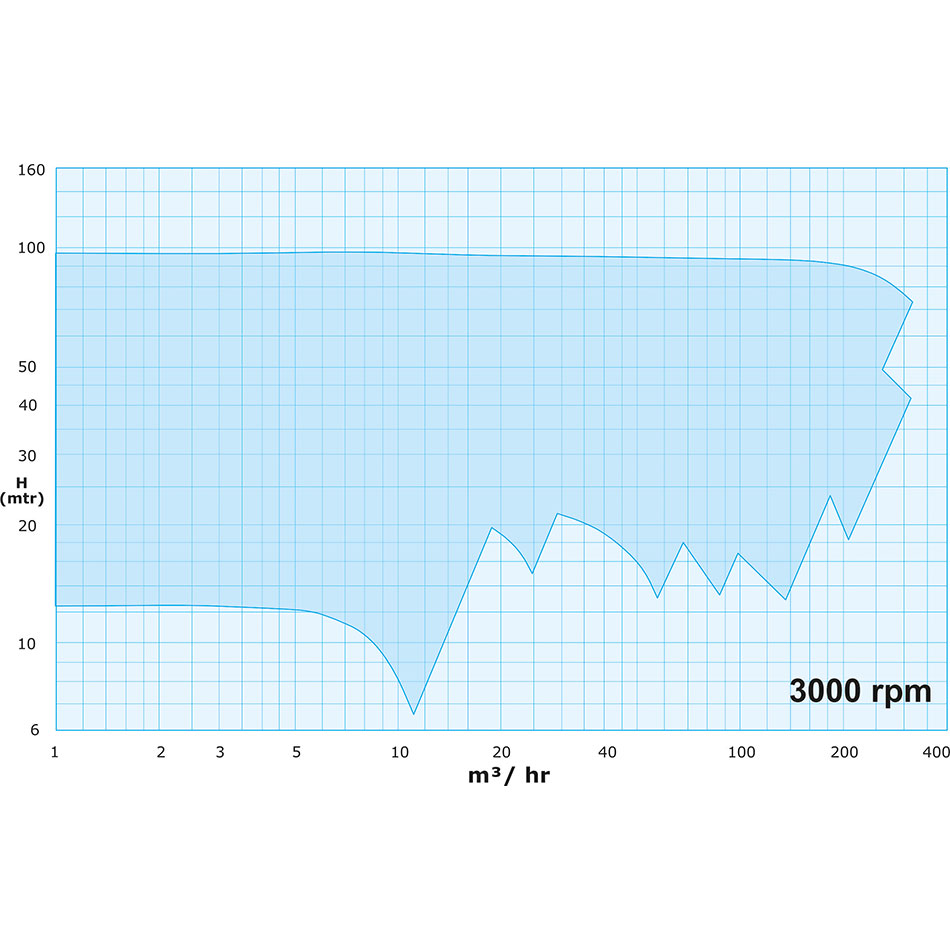

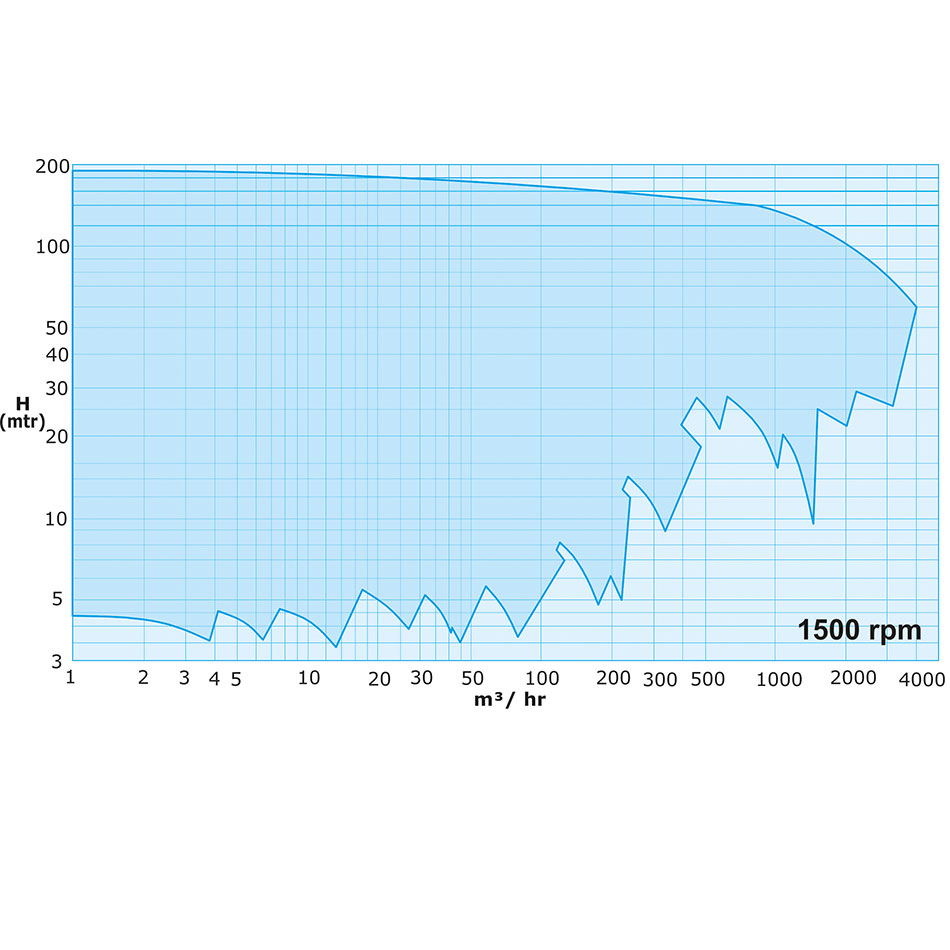

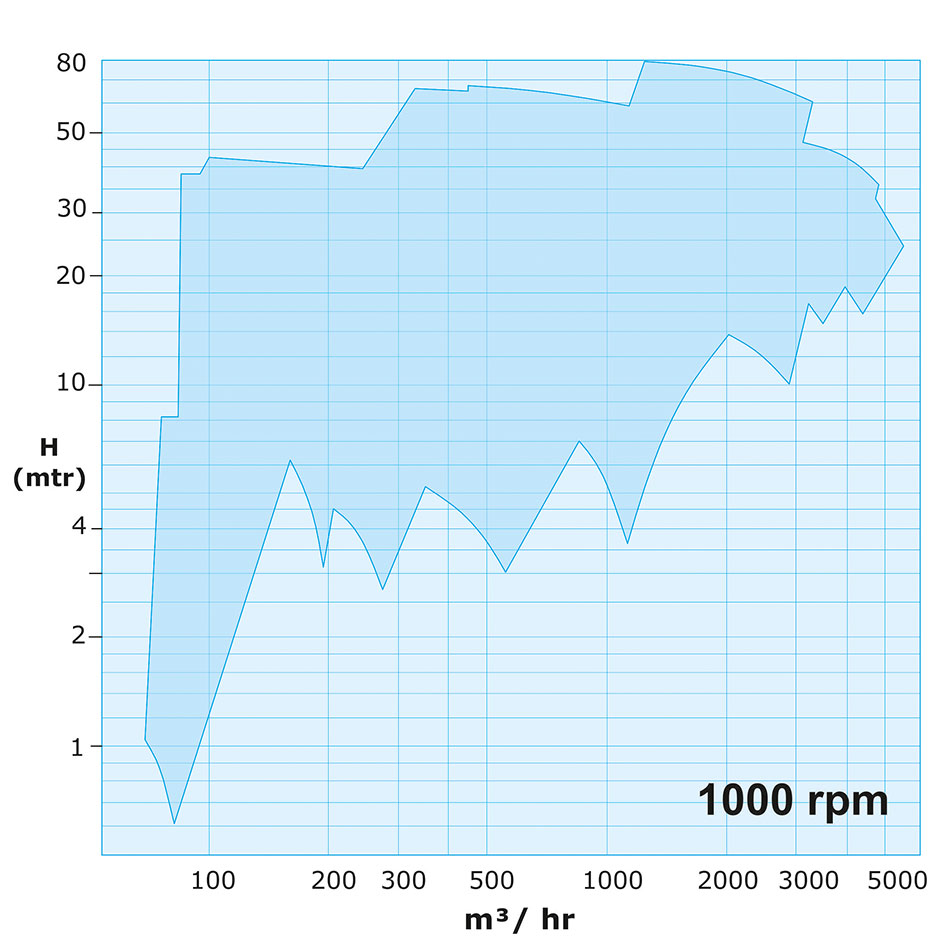

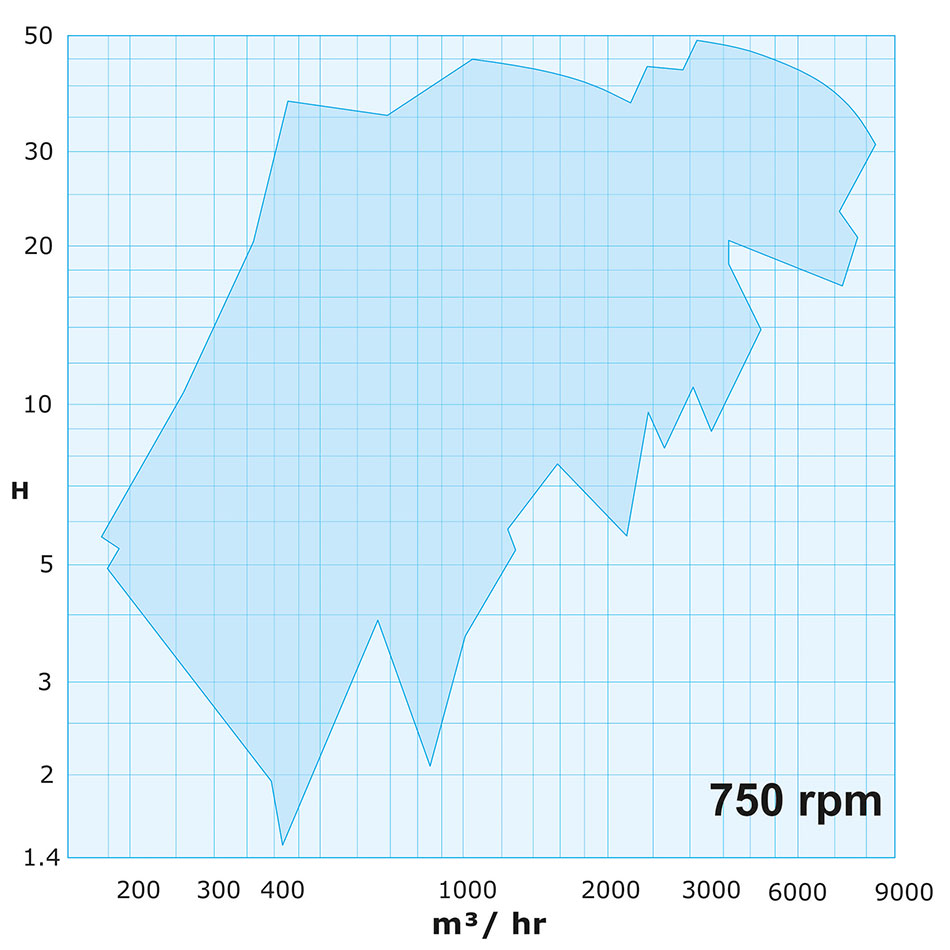

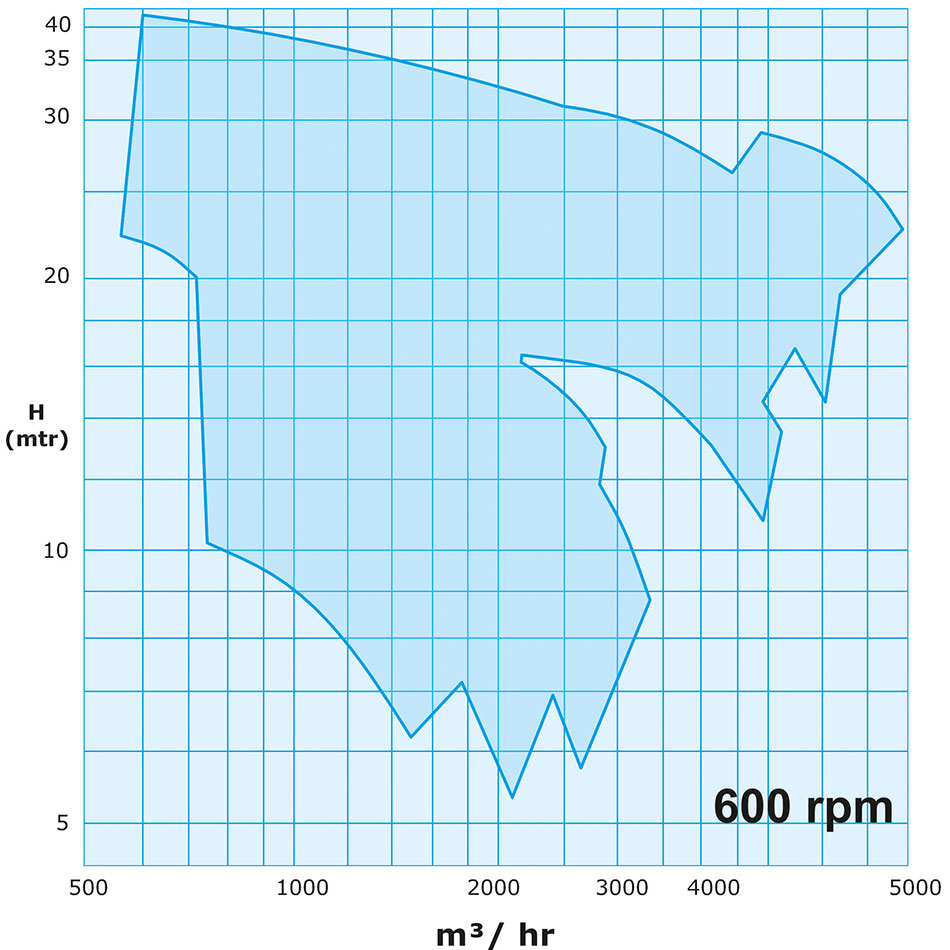

Typical Performance Range

-

Application

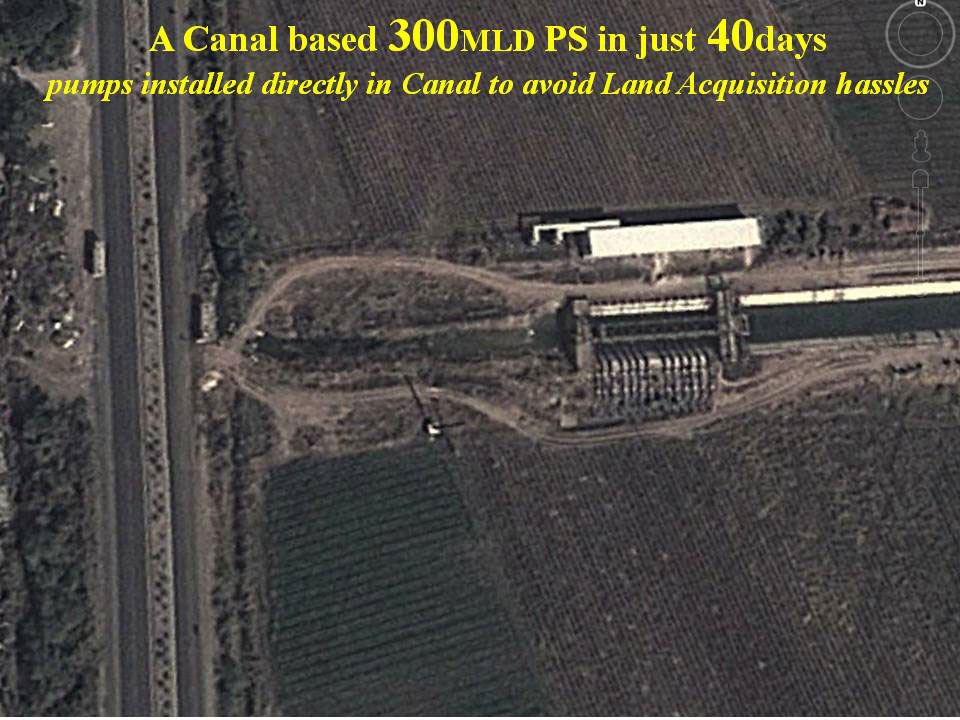

Sadulka - The Engineering Marvel

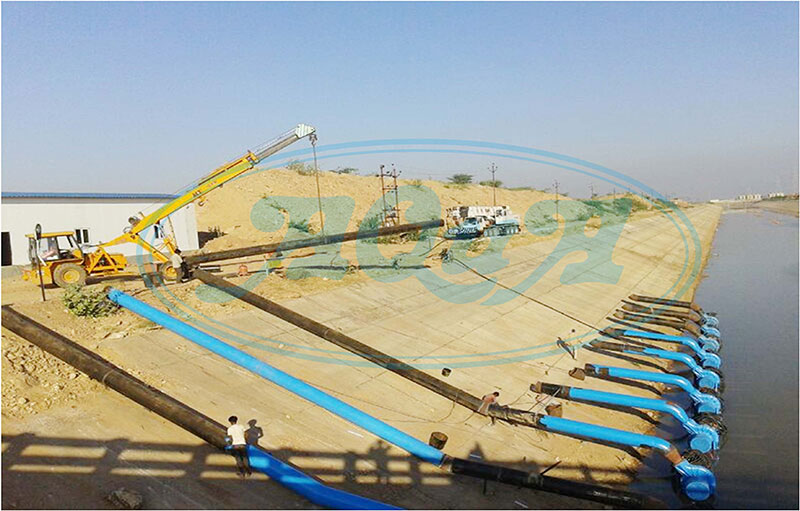

The Open Canal Pumping System on Dhangadra Branch Canal, Gujarat.

An Administrative wisdom and Engineering Marvel - Commissioned 300 mld canal based WSS (complete with Civil + E/M works) in a World Record (just 40) days to mitigate water scarcity. Such fast timing is due to the fact that the pumps are installed directly into the canal itself & the client has saved crores of rupees in HR, Pump Room costs & could compacted the project duration from 18/24 months to just 40 days...!

Dudhrej

A 182 mld canal based pumping station : SubCF pumpsets of 100 m head & 600 hp, directly installed to the canal.

By utilizing existing spareable SubCF pumpsets & buying some new ones, GWS&SB has commissioned a direct canal based pumping station of 168 to 182 mld charged NC 33, 34 -pipelines to deliver water to Rajkot via Hadala.

Chavand :

Transmissions pumping station : GWIL has commissioned 200 mld & 175 mld water boosting pumping stations with latest technology pumps thereby out rightly eliminating pump rooms, huge Capital & Life Cycle Cost savings.

Line of Action to Commissioning within 90 Days : A 208 mld Chavand Pumping Station having SubCF pump sets of 110m Head and 600hp.

Vadia :

Due to drying up of local source (Ojhat dam), Junagadh section was facing huge water shortage. To tackle the situation, GWS&SB setup a Booster Pumping station thereby augmenting the Dharai-Junagadh bulkline's Carrying capacity (up to twice or even thrice) in just 2 months - i.e at 1/9th Time duration.

95 m head & 550hp SubCF pump sets directly lowered in RWR - A 120 mld Pumping Station, LoA to commissioning within 60 days.