"India's Largest manufacturer of Heavy Duty Non Clog Submersible Sewage pumps"

ANS pumps are specifically designed (as an upgrade over the 1st generation of submersible non clog pumps) to withstand the harsh operating conditions (encountered in sewage pumping) in developing countries.

Unique Advantages of Aqua's ANS

- Best long term maintenance free track record in India

- VFD compliant Inverter duty motors

- Tolerates wide Electrical supply fluctuations

- Zero Routine maintenance requirement

- Pumps factory tested on Full Scale Test Bed equipped with VFD up to 1180kW

- Wide range of Hydraulic designs allow Clog-less handling of sewage at optimal efficiency

- High pump efficiency is sustainable over longer periods due to Smart Set hydraulics

Why the 2nd generation of "ANS" Submersible Sewage pumps?

A concept for 20th century Europe a pump for 21st century World !

The 1st generation submersible non clog pumps used in India were either designed for European conditions or based on these European pumps ( either through inspirations or collaborations ). However the Indian (& most developing countries) have operating conditions that are drastically different ( much harsher on pumps), like :

| Condition | Effect on Pump | Result |

| Poor Electrical Supply | Motor Insulation Stressing | Premature motor burnout |

| Higher Ambient Temperature | ||

| Poor liquid level sensing & operation by often unskilled staff leading to frequent Dry Running | Excessive heating leading to motor insulation burn out, bearings grease leakage & possibly seizure ; Mechanical seal overheating | Immediate motor, bearing & mechanical seal failure |

| Poor or defunct Solid Screening leading to high concentration of solids, especially fibrous ones | Dangerous cocktail of large solids & fibrous waste plait up & choke conventional non clog impellers leading to motor stall | Immediate Motor Insulation burnout |

| accelerated erosive wear of impeller Leakage Clearance | Drop of pressure & efficiency |

hence their performance in India was below the mark. Aqua engineers were amongst the first to realize this mismatch between design & operating conditions. Here the concept of ANS was born - ANS is the First 2nd second generation of submersible sewage pump specifically redesigned / upgraded for operating conditions of developing countries.

-

Installations

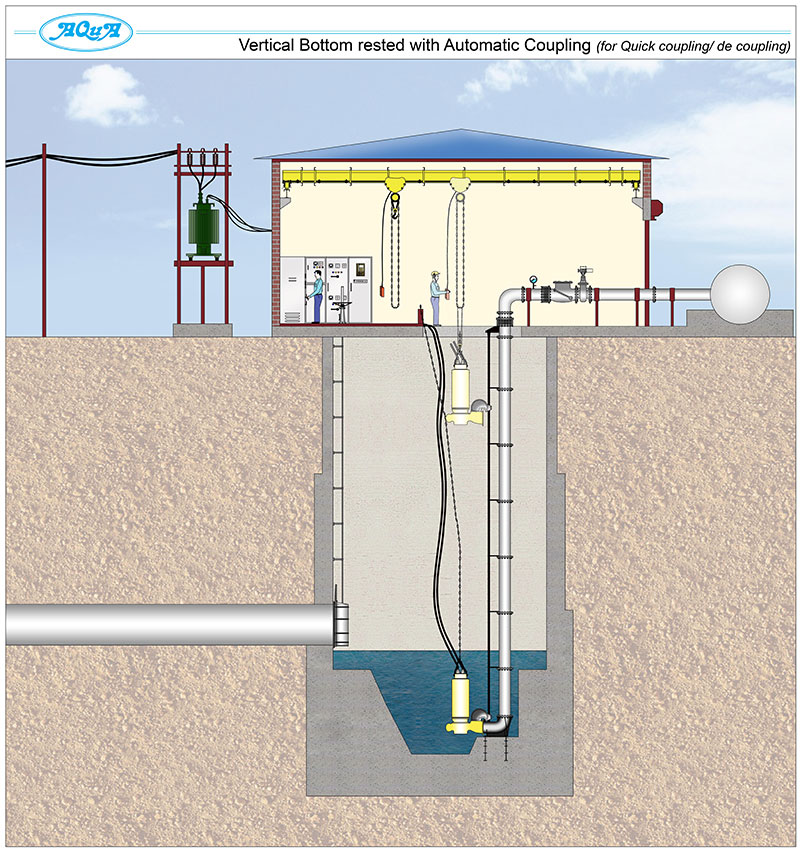

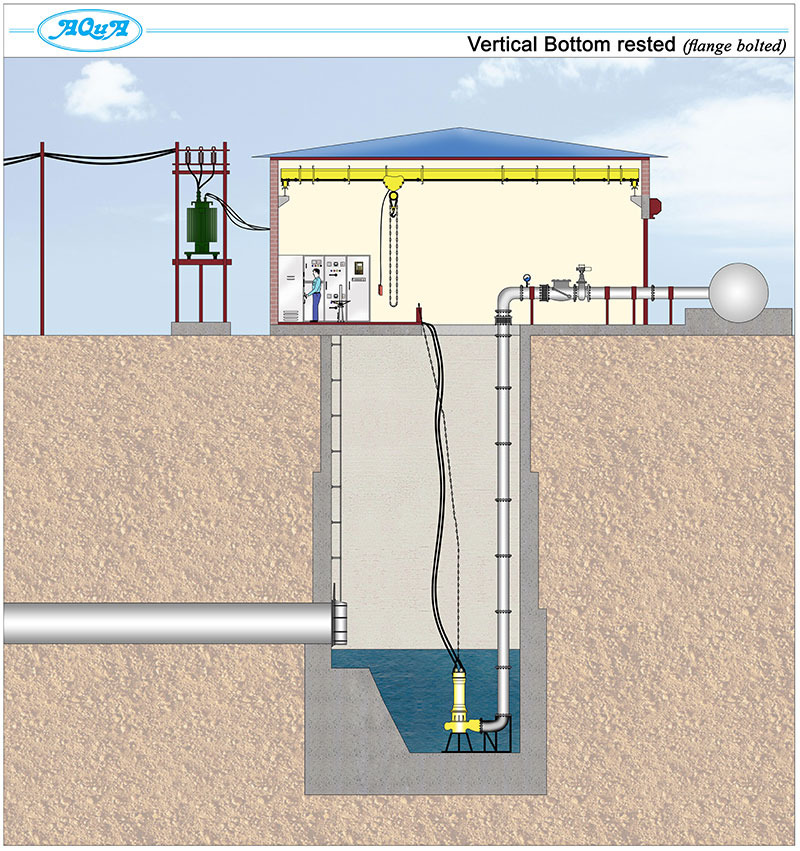

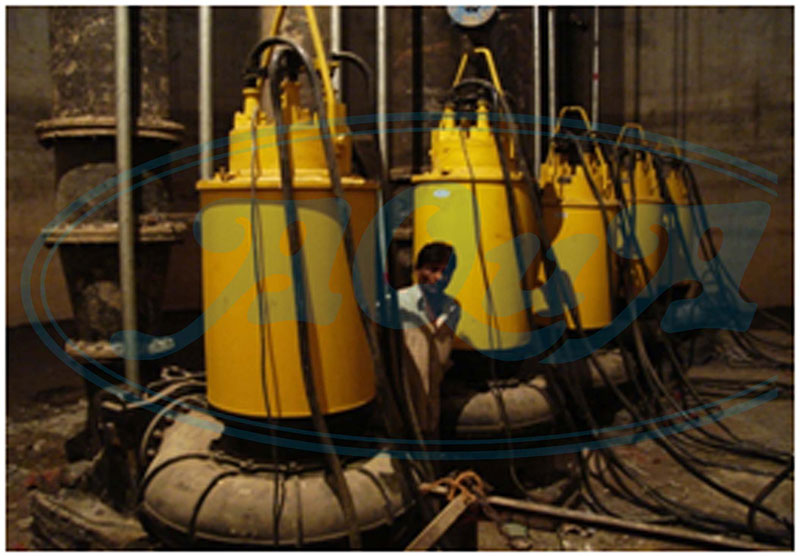

Permanent Wet Pit Installation

This represents the cheapest & most user friendly pumping station design. The pump is installed directly at the bottom of the wet pit using Aqua automatic coupling system. This system ensures that the pump is properly lowered (& firmly connected to the discharge piping) or Lifted out (disengaged from line) in a simple, precise & quick way. This system includes guide rails (which guide the pump correctly downwards) till its discharge flange matches that of the auto coupling pedestal. The contacting surfaces are well machined & designed such that the weight of the pump & wedge design of Auto coupling ensure a leak free joint. The pump is kept in place by its own weight - there is no need for any fasteners to clamp it to the delivery piping. Removing the pump for maintenance is equally simple - just pull it up; there are no bolts to be dismantled. The operator need not enter the septic sump once the automatic coupling system is fitted.

Minimum Liquid Level

If site conditions dictate minimal depth of excavation ( & hence a higher sump bottom /eve/ ); Jacket cooled motors can be (optionally) offered allowing the pumping to almost the casing level of the pump. Aqua's wet pit jacket cooling system is field proven to be clog resistant in Real life Indian sewerage condition. It uses the pumped media to dissipate motor heat & hence does not require any additional coolant/ impellers

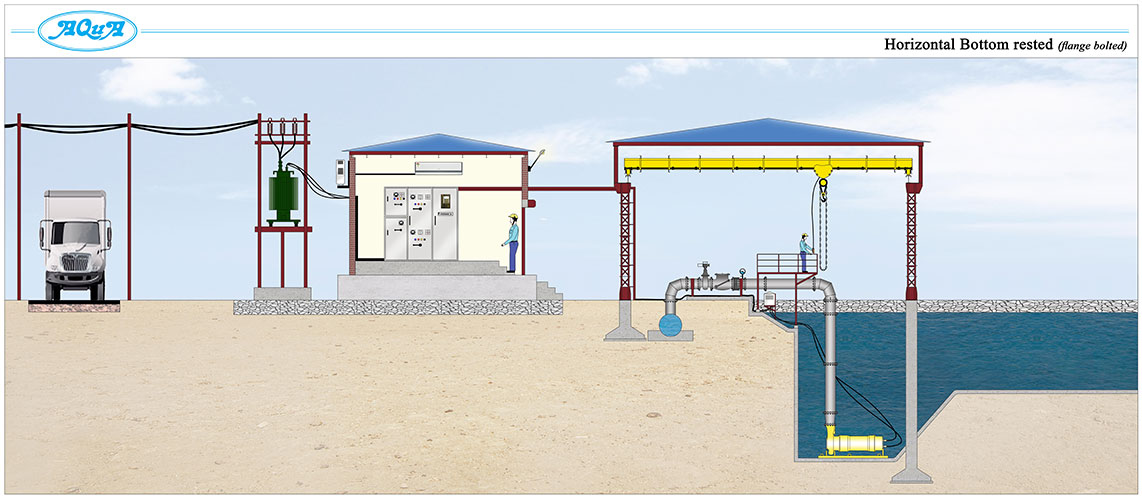

Aqua offer an option of close circuited jacket cooling systems (utilizing special coolant& internal circulation impeller ) for cases where the pumped liquid is very corrosive or very thick. Flood Proof Insurance for your dry pit type drainage pumping stations-dry installed submersible pumps!Horizontal Bottom rested (flange bolted)

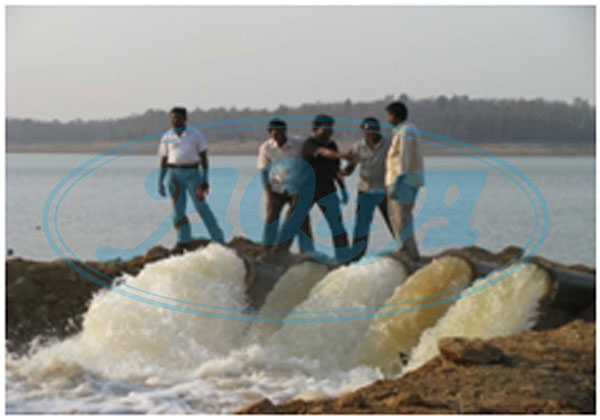

Submerged Portable Vertical installation

Certain applications like sewer pipe line construction / maintenance works, salvaging flooded dry pits in pumping stations, replacing aged dry installed pumps (by mounting the ANS pump directly in the wet pit), drainage of open sewer drains; require submersible pumps to be installed on transportable portable stands. ANS pumps can be factory fitted with portable skirt base stands enabling quick & versatile installation — they can be fitted either Vertically or Horizontally

-

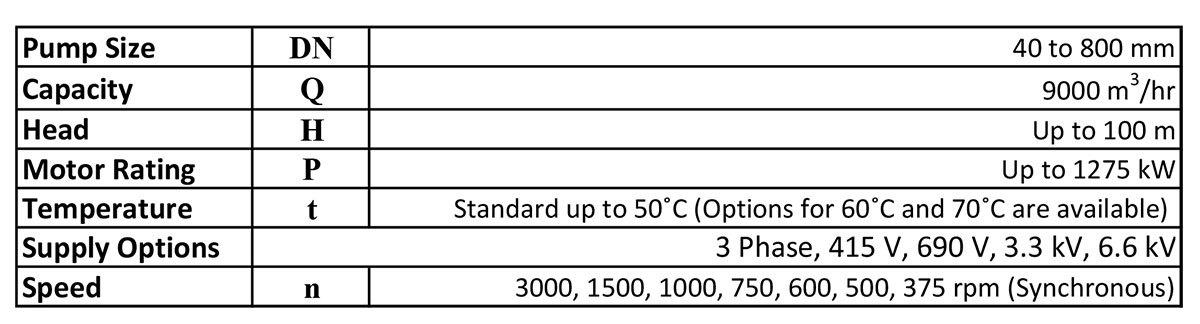

Technical Specifications

-

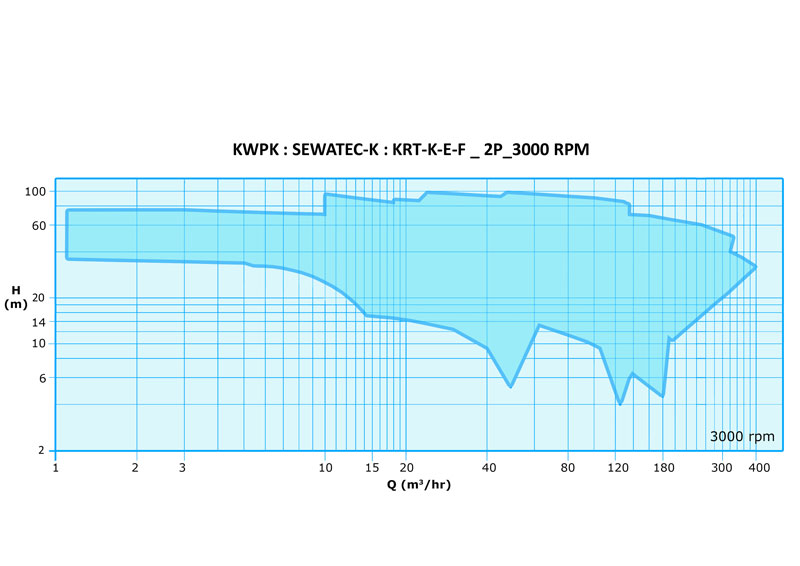

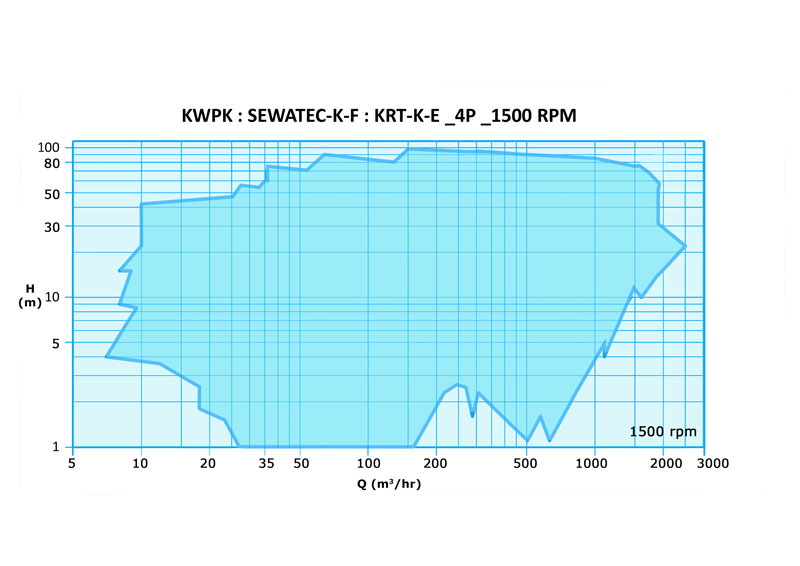

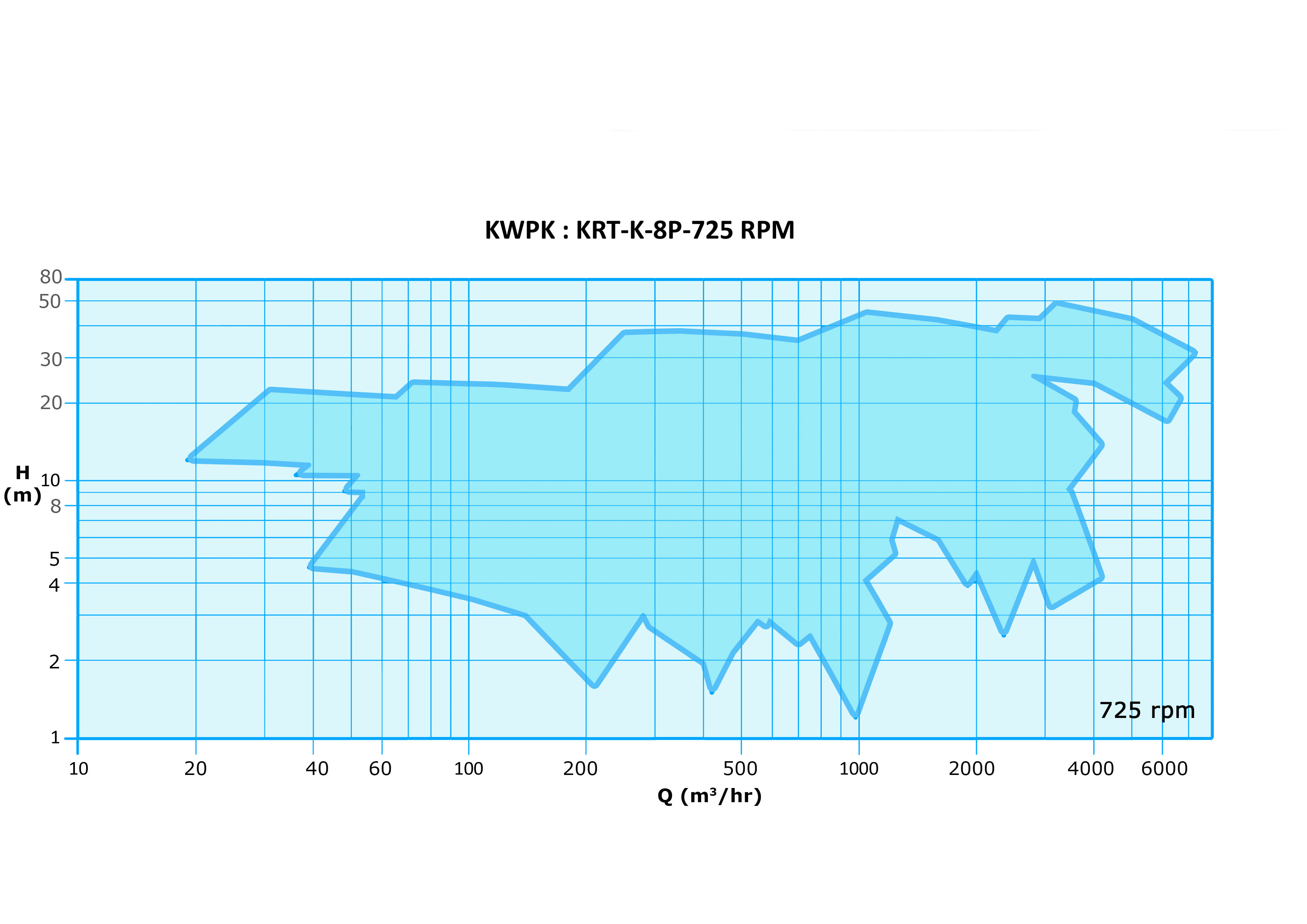

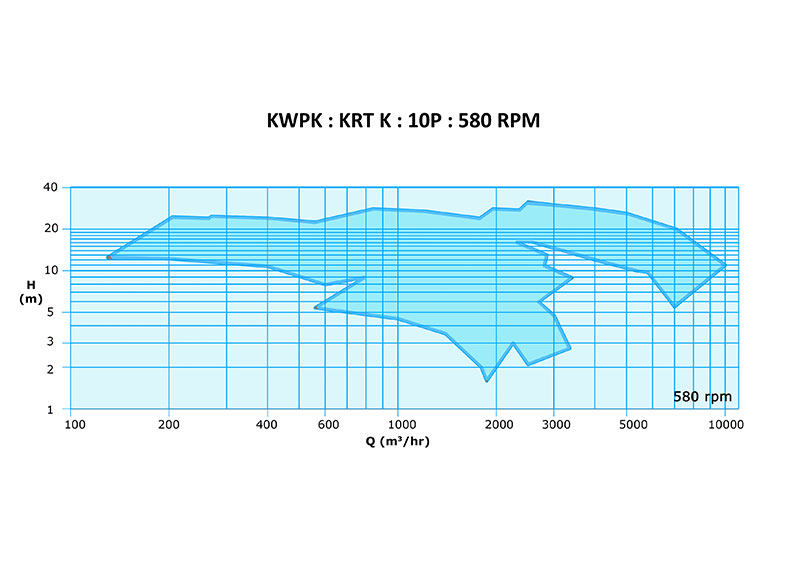

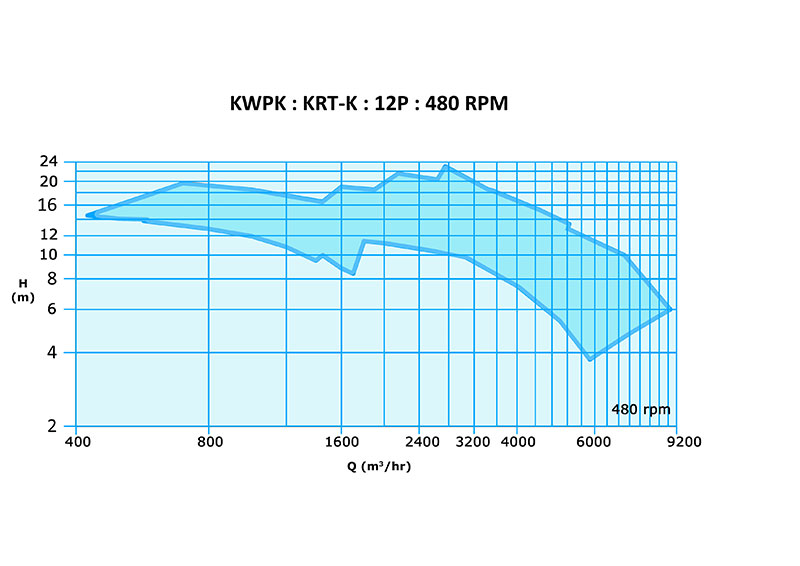

Typical Performance Range

-

Application

The Buddh International Circuit in Noida, UP is India's answer to the world for Formula 1, Grand Prix. Spread over an area of 874 acres (354 ha), it is 5.14 km long & cost about $215 million to build. Being spread out over such a vast area, it required around 165001ps of Storm Water pumping m/c to prevent the track from water logging. Aqua Submersible Drainage pump sets cumulating 59400 m3/hr drain this world class race track.

India’s Largest Sewage Treatment Plant (of its time, based on sub pump sets for raw sewage intake) runs on Aqua’s Sewage Submersible pumps (12nos x 300hp x 1791 m3/hr)

For one of India’s Largest River Cleaning Sewage Interception project (Sabarmati River - Ahmedabad); Kirloskar Brothers Ltd. uses Aqua make sub sewage pumps (up to 2100 m3/hr-240 hp each & totaling 42,000 m3/hr - 5300 hp)

One of India’s Largest Storm Water Drainage project (SWD-Ahmedabad) runs on our sub NC pump sets (up to 2400 m3/hr each & totalling 1,32,000 m3/hr & 9400 hp)

One of Sri Lanka’s Largest Sewage Pumping Station uses our sub pump after they have outperformed more established global makes (measured as a function of lower clogging & lesser breakdowns).

Surat Municipal Corporation uses Aqua's 130 hp Dry Motor Sub Sewage pumps to SCAVENGE the residual sewage from its wet pit (which the old VNC pumps can’t lift) – it has worked without a single maintenance call in 8 years